GreenTower

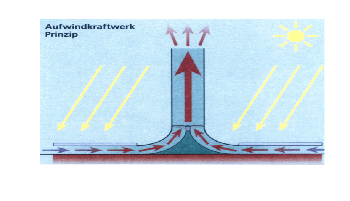

GreenTower | | GreenTower Working Principle |

GreenTowers supply emission-free and sustainable the cheapest power, food + fresh water · GTs directly utilise the largest energy source, the sun; energy stores supply full power day and night · At 1,5 €c/kWh cheapest power in the solar belt (30° north/south), China, India, Australia etc. Using high-voltage DC power lines cheapest power at 2,0 €c/kWh in Europe, Russia, Japan, USA, Korea etc. · GTs utilise 2/3 of collector as greenhouse ⇒ return on investment ≥ 30% without carbon certificates · 8 GTs in Namibia sequestrate ± 120 million ton/y CO2 as humus in soil ⇒ carbon credit revenues = €3b · Cheapest desalination in hot central part of GT collector supplies large amounts of fresh water · Lowest prices + highest profits of all power technologies ensures quickest market penetration · Full insurance of design, construction and power output reduces risk of investment to practically zero · Up to 30 000 jobs/GT ⇒ people in developing countries don’t need to emigrate any more | | • Visible (also diffuse) radiation (λ = 0,5μ, green light) heats the floor in the glass-covered collector, • this heats the air by convection (hot air near floor ascends and mixes with air in collector). • But: Floor radiating in the infra-red (λ = 10μ) heats the IR-absorbing glass, which radiates into space (loss proportional to T^4, T in Kelvin). IR-reflection layer at bottom side of glass + insulating glass panels reduce heat/power loss enormously; one of many special achievements of the GT. • Buoyancy (weight difference air inside/outside) causes an updraught (sucking) in central chimney • Updraught drives 32 turbines at circumference with integrated generators at chimney foot. • Water stores store heat and re-supply it in a controlled manner to the air ⇒ day and night full power • The outer 2/3-collector area is used as a greenhouse with vegetation and humus soil: • Losses in evaporation energy are recovered by re-condensation, humus soil soaks up the recondensed water like a sponge, no puddles, no root diseases. |

GreenTower Specifications

• Flue height = 1 500m ; flue Æ = 180-280m;

collector-Ø = 6,9km; roof height: outside 10m,

inside 30m

• Power rating 400 MWel, emission-free; efficiency

4% at present, future potential 14%

• 32 turbines at flue circumference with integrated

linear generators, 6 day fast-response + seasonal

energy store, controllable, power at any time

• GreenTower® collector: Air heating (power) +

greenhouse (food)

• Food production/GT/y for at least 400 000 people

• Collector area 37,5kmÇ: inside 12,5kmÇ; area

greenhouse = 25kmÇ; related plantations = 82kmÇ

• Drip irrigation, controllable shadow nets

• Humus from GT composting of unsold residual

biomass will be buried in the soil

• CO2 sequestration per GT + related open-air

agriculture » 15 million ton/y CO2 » 2 000 MW

from coal-fired power station emissions

• Only sequestration which can be certified due to

the high long-term stability of GT humus

• No prior CO2 separation required at emitter site;

GT extracts CO2 from atmosphere

• Only proven technologies

• Construction period: 3 years

• Technical part: Design life-span 160 years

• Capital cost (extrapolated tenders): GT (only

power) ± €525 Mio; greenhouse implements: ±

€110 Mio; solar glass factory ± €75 Mio, total = ± €710-800 Mio

Projekt :

Green Tower

Kurze Information

Nutzung:

-die größte Energiequelle für die Nutzung von Green Tower ist die Sonne ⇒ direkt – und jederzeit Strom durch Energiespeicher

-konkurrenzlos durch die billigste Anbietung vom Strom im Wert von 1,5 € c/k Wh im Sonnengürtel

-Sie nutzen 2/3 des Kollektors auch als Treibhaus ⇒ Investitionsgewinn ≥ 30% ohne Zertifikat

-Süßwasser Erzeugung in größtem Stil bei niedrigsten Entsalzungskosten im heißen GT – Kollekturzentrum

Funktion:

Sichtbare Strahlung erhitzt den Boden im glaseingedeckten Kollektor

-Steuerbare Wasserspeicher speichern die Wärme und geben diese kontrolliert ab;

⇒Tag und Nacht Strom

-Durch Rekondensation werden die Verdampfungsenergieverluste wieder gewonnen, Humusboden saugt rekondensiertes Wasser auf ⇒ keine Pfützen , keine Wurzelkrankheiten.

GREENTOWER: RISK ASSESSMENT

1. General

The Solar Chimney/GreenTower® (GT) is often portrayed by adversaries as a high risk technology due to the tall chimney of 1 000m to 1 500m, the large collector of 37,5 km², the allegedly “unproven” energy store, the alleged uncertainty of the amount of power generated and the perception that the GT represents only a concept rather than an experimentally proven and mature design. We shall show below that these perceptions are wrong.

The risk of functional failure does not exist, since the driving force, the natural updraft with no moving parts is guaranteed by basic laws of physics as long as the structure exists and the sun is shining. As the up-draught drives 32 independent turbines, the functional failure of which is highly unlikely due to friction and maintenance-free, self-centering magnetic bearings and integrated, maintenance-free linear generators with stationary functional controls, the risk of simultaneous failure of two turbine-generators with a 6% loss in power generation is ± non-existent. Note that all technologies used are state of the art, only the combination is new.

Prof. Schlaich’s Solar Chimney pilot plant in Spain operated between 1982 and 1989 without a single second outage for faults as a first of its kind, seven years in a nearly continuous operation and 32 months in fully automatic mode without touching a button, better than any other technology. This shows the GT technology to be most reliable and the concept to be sound.

Moreover, calculated and measured annual energy output matched within half a percent, though only a “standard atmosphere” was used in the calculations of the ambient atmosphere instead of exact values for the full height of the chimney. It will be shown below that this model will be refined to perfection by using real time measured data for the ambient atmosphere.

Adversaries often point at the pilot plant’s chimney flue being blown over by a heavy storm in 1989 but neglect to mention that a cheap, lightweight, dismantle-able construction was used to be removed after three years, where after eight years of service the heavily rusted rod stays were to be replaced but the money arrived just too late. The facts can easily be verified.

An example that even a much less developed and researched technology can successfully be implemented is the SEGS 356MW solar trough power station array in California which started with no more than a power purchase agreement and a concept which was further developed and refined during the building period. Teething problems were solved thereafter. It has now been working successfully for 18 years. Please note that the GT technology is by now incomparably more refined and mature due to the pilot plant in Spain and fundamental additional experimental and theoretical research at 10 universities and 31 other research centres. The foregoing shows, that already in 1996 the GT power technology was mature and did not show undue risks.

2. The Chimney Structure

Adversaries go as far as stating that a 1 000 or 1 500m chimney would collapse under its own weight, thereby showing a severe lack of understanding basic physics. To build such a chimney flue is always possible, if the (over-dimensioned) wall thickness increases downwards. The question at stake is whether it is possible with a thin-walled reinforced concrete structure at affordable cost. The foremost experts, Prof. Schlaich and Prof. Krätzig, showed that such a 1’000/ 1’500 m thin-walled chimney flue can stand the wind load of a standard atmosphere, provided the flue-cross-section keeps its circular shape, which will definitely be ensured.

In this case only compression and no tensile stresses will occur so that a reinforced structure, which will be used here, can stand even higher wind loads by virtue of its reinforcement. The secret lies in the insertion of equally spaced “spoke wheels” which will keep the cross section circular and prevent denting.

The same result has been found without exception by all other leading experts. Only non-experts see risks here. In the finite element analysis the well known static wind forces and the periodic wind forces caused by periodically detaching whirls at the chimney´s lee side (Karmann whirl system) have been included with an accepted safety factor for “atmospheric turbulences”.

Meanwhile these “atmospheric turbulences” have been thoroughly researched by Prof. Niemann´s team at Bochum University, the present world leader in this field. Not only have they developed an excellent modeling of periodic wind forces due to predictable turbulences in the atmospheric boundary layer, but their “long entrance” wind tunnel is at present the most advanced tool to determine these periodic forces experimentally. Incidentally, the differences between wind and gusts strongly decrease with height and disappear at 1 500m. The GT-1’500m-flue will also be tested there and in the unlikely event that resonance might occur, cheap and effective remedies are available. Hence the last remaining slight uncertainty has now been removed and the GT chimney will be one of the safest structures ever built.

Besides this structure being extremely well researched, design and structure will be fully insured and double-checked, so that the risk of structural failure and financial loss is virtually zero.

3. Risk of Earthquakes

Due to the September-2005-Kashmir-earthquakes of magnitude 8,1 the question arises, whether a 1 500m tall chimney flue would not pose too high a risk for a GT in Rajasthan. A seismic map of India from 2003 shows the different risk zones according to seismic activity in the past. The dark red zone V shows the highest risk of seismic activity where earth-quakes of magnitude 8 or more might occur, which greatly coincide with the southern seam of the Himalaya Range where the tectonic plate of the Indian subcontinent is sliding in below the Eurasian tectonic plate, i.e.

the Tibet Plateau by 4 to 5 m/100 years, of which 2 m/100 years is stored elastically in the Himalaya Range, which energy is released in earthquakes. At present an 8 to 12 m elastic compression’s energy is stored in the southern Himalaya so that alongside its whole border line heavy earthquakes are indeed overdue with the Kashmir earthquake apparently being the first.

Notably New Delhi in the medium red zone IV had between June 1992 and November 1994 eight earthquakes of magnitudes between 2,5 and 3,5 not leading to any recorded damage, which shows that seismic activity and the risk of heavy earthquakes quickly decrease with increasing distance to the southern Himalaya seam. Hence the area for the envisaged 4 GTs near Jaipur, Rajasthan, in the yellow zone I shows for practical purposes no seismic risk at all.

If, however, a slight seismic risk would be sensed in for instance the pink zone III, GTs could easily and cheaply be stabilized by cables from the 7 compression rings of the spoke wheels (for a circular cross section) down to the outer foundation circle of 600-700m diameter. Hence GTs can be built in nearly the whole of India with small structural changes without any undue risk. Earthquake-resistant structures for high risk areas are available but at higher cost.

In the unlikely event that the seismic risk in a given area has been completely misjudged, the worst case of the 1 500m chimney flue coming down can never result in heavy loss of life, as only 3 persons are present in the central collector area with a radius of 2km. The greenhouse workers are automatically protected against broken glass by the shadow nets and the collector structure can be made earthquake-resistant at low cost.

This stands in sharp contrast to the envisaged 150 000MW hydro power from large river dams at the outskirts of the Himalaya valleys, all of which are prone to complete failure through earthquakes above magnitude 8 soon to be expected. Compared to the tenfold increased population density in the Ganges River system since 1934 loss of human life would run into millions, if the envisaged dams would fail. Since the power potential of the rest of the country is only about 10% of the Himalaya-rivers, hydro power can due to this high risk not contribute significantly to the future power mix in India. Small flow of the river power stations would not only diminish the hydro potential by 70% but would make hydro power unaffordable.

The GT sites in Namibia-Botswana, UAE-Oman etc. carry no seismic risk.

4. The Large Collector

Since adversaries and surprisingly also the renowned US research unit Sunlab are pretending that the large-GT-collector/high-yield greenhouse poses a grave threat to the environment requiring an expensive in-depth impact assessment and possible prohibitive actions, we have to address this “risk” here. Have forests, including tropical rain forests and large farming areas suddenly become a “grave threat” to the environment, or was Sunlab jesting?

The thermal up-draft caused by the sun heating the ground is the real cause for all winds and jet streams in the atmosphere, rain, storms and the global wind system with the sea currents. If this up-draft is inhibited by very large, densely packed PV panel or solar thermal mirror fields, the solar radiation does not reach the ground and the up-draft is stopped with negative effects to the atmosphere and the environment. Contrary to that, the GT and Prof. Schlaich’s Solar Chimney do not inhibit the up-draft, but concentrate it at the chimney flue to a height of 1 000 m/ 1 500m, above which it mixes again with the ambient atmosphere undoing the concentration. The GT can thus be applied at any scale without any environmental risk.

A great concern with all solar technologies is the extensive use of land due to the sunlight’s low energy concentration. However, no land is sterilized by the large GT-collector, since the GT-greenhouse will increase production of a highly productive agricultural area from 100% to at least 270%, adding a virtual 170% to the existing land. These calculations are mainly based on Prof. Kröger’s experimental and theoretical findings in 2000, showing that vegetation in the collector increases heat and power production – a breakthrough in GT research! The high greenhouse yields and profits have been established by the Roodeplaat Research Centre, Pretoria, the Zentrale Markt- und Preisberichtstelle, Bonn, and others and have been calculated very conservatively, so that no risks are involved regarding the financial forecasts for the greenhouse’s profits, whilst in India the relation of profit to cost is even better.

The conversion of the greenhouse’s large amounts of biomass to humus to be buried in the soil resulting in high CO2 sequestration makes the GT, in addition to the lack of any environmental risk, the purifier of the atmosphere, reversing the greenhouse effect, if applied at large scale. The GT-tendency to become the nucleus of an ever increasing oasis makes it the natural driving force to cultivate the globe’s huge desert areas, leading to a general improvement of the earth’s climate. Experimental research proved a root growth of one meter in three days by optimal use of humus, as in the GT, so that sane organic agriculture will be combined with the highest possible yields. Seeing all these environmental advantages we conclude that Sunlab was jesting indeed by labeling the large GT-collector a special threat to the environment. Contrary to Sunlab’s surprising lack of insight we note that also the GT-greenhouse is very well researched, minimizing any potential risk in production or profit.

5. Agriculture in the Greenhouse

As the GT-collector becomes progressively hotter toward the centre, many questions arise about the risks of soil-based agriculture in this huge, air-cooled greenhouse:

-Question: Will the strong winds in the greenhouse affect the plants negatively?

Answer: No, since the horizontal shadow nets will effectively separate the air space above and below. Strong winds will only occur above these nets.

-Question: Can the plants stand the high temperatures of a hot summer day + additional heating?

Answer: The continuously adaptable shadow nets will limit the visible radiation below in a controlled manner during the day, so that incoming radiation, causing heat, will be restricted. Water evaporation associated with CO2 assimilation during the day causes strong cooling, so that these combined effects always keep the plants below the stress temperature.

-Question: Will the shadow from the nets reduce plant production in the greenhouse?

Answer: On the contrary: With a 50% translucency of the shadow nets the visible radiation below is nearly 100% diffuse, reaching all parts of the plant and not only the top leaves. Assimilation and plant growth is thus much higher as also a sound cooling by evaporation.

-Question: Will the daily 22 hour airtight separation of corresponding greenhouse compartments for re-condensation of water cause CO2 deficiencies?

Answer: No, since additional CO2 will be supplied from other GT sources at no cost.

-Question: Will the puddles of re-condensed water on the floor cause root diseases?

Answer: No, since the soil will absorb the condensed water like a sponge due to its high humus content and distribute it evenly in the soil through the fine humus capillaries.

-Question: Will certain (pseudomonas) bacteria in the soil, which are normally removed by frost, not cause serious root diseases?

Answer: In the GT greenhouse frost does not occur, but the killing of these germs can also be done by heat. With open shadow nets at mid-day 90°C at the soil surface will kill them.

-Question: How do you remove seeds from preceding crops from the greenhouse soil?

Answer: Even with meticulous working one cannot remove all seeds before planting a new crop. One thus prepares the soil well and let the seeds germinate. A temperature of 90°C (shadow nets open) and no water will kill the unwanted shoots. As the wanted crop is planted thereafter, the old seed cannot interfere anymore.

-Question: Will the soil-based big-greenhouse agriculture not sustain all sorts of plagues?

Answer: This would be true with a standard soil but is not true with the GT-humus soil, containing high concentrations of natural antibiotics, which will check all plagues. The very fast root and plant growth in the GT often causes the plant to outgrow the plague/disease.

-Question: Will the intensive GT-agriculture not exhaust the soil very fast?

Answer: The assumption underlying this question is that all nutrients for a given crop have to be added to the soil before planting. In general, however, the nutrients are already in the soil. It needs the right organisms to break these mineralized nutrients down and to make them root accessible. As the special GT-humus will enhance soil life by the factor 1 000, all the necessary organisms will be present and will find the best possible environment to abundantly supply plant nutrients. The more humus is present in the soil and the better the quality, the more new high quality humus will be formed from old root material, as artificial resting periods for the soil can be managed in the GT-greenhouses.

-Question: Will the high greenhouse production not starve through nitrogen deficiency?

Answer: As nitrogen-fixating bacteria, free-living in the soil, can supply enough nitrogen to the plants, if the humus content in the soil exceeds 10%, 12% humus and the corresponding bacteria will be added to the soil (33cm deep) at the beginning. Thereafter no further nitrogen fertilization is required, as the bacteria multiply according to root growth.

-Question: Is this humus agriculture not very expensive and thus financially risky?

Answer: As eight million ton of “mature compost” have been offered to the author f.o.b. port North Sea to be transported by huge ore carriers, returning empty to South Africa, compost can be brought to the whole African west coast at cheap back freight rates. Initial surveys show that biomass for composting can be obtained in Rajasthan at ± the same or lower cost. Hence the GT-humus-agriculture is financially more rewarding than its current power production, which in turn is the most rewarding of all present power technologies.

Hence there is no financial or environmental risk involved in the GT greenhouse high-intensity agriculture.

6. The Turbine

Firstly we note that Prof. von Backström of Stellenbosch University achieved a great breakthrough by increasing the low air/angular speed turbine’s (fan’s) design efficiency from previously 70% to more than 90%, which is demonstrated by several models there.

After the original Schlaich (Voith) turbine design shrank to 130m for problems with conventional generators, it became too small for the efficiency/cost-wise advantageous GT-1 500m-chimney.

Linear generators (used in Transrapid trains) at the circumference and maintenance-free permanent magnet bearings are now used for the 32 integrated GT-generator-turbines of 30m Æ. Since rotor blades are also suspended at the circumference, stresses in the central hub are minimal, prolonging life expectancy significantly. These wear- and friction-free bearings are self-centering, excluding damage through imbalances, which in 2003/4 destroyed four 700MW steam turbines in South Africa. The new design minimizes technical/financial risks and saves cost.

7. What makes the GT Technology so Reliable?

The seven year faultless, nearly continuous operation of Prof. Schlaich´s Solar Chimney (SC) pilot plant in Spain, the best result of any power generating technology hitherto, was no accident, as it is by its very nature the most simple and reliable (heat) “engine”:

A. Heat Generation

¨ GT collector: Heat is generated stress-free solely by the visible solar radiation, being absorbed in the soil and raising air temperature in the collector by 76°C; no moving parts;

¨ Fossil fuels: Tedious mining/drilling/pumping operations; complicated transport to the combustion chamber of an internal or external heat engine; high heat (1 100 to 1 300°C) and mechanical stress in the internal and external combustion chamber; complicated mechanical fuel injection and ash removal under high temperatures; heat transfer from combustion chamber to boiler of steam engines through fume pipes under high boiler pressure in an aggressive medium.

B. Pressure Difference – Mass Flow Generation

¨ GT collector + chimney flue: Pressure difference inside the GT is less than one bar and causes a gentle sucking action in the chimney through the weight difference between the hot, light air inside the chimney and the cooler outside air, using a low temperature difference and a non-aggressive medium (air); no gusts; no stresses; no moving parts;

¨ Fossil fuel technologies: High pressure (90 bar plus) and temperature (550°C plus) in ex-ternal boilers and shock waves (several 100 bar) in internal combustion engines, aggressive working media (hot steam, combustion fumes) and high wear on piston rings, turbines;

¨ Hydro power: Medium pressure (10 to 30 bar), aggressive medium water; wear on turbines;

¨ Wind generators: Very high stresses in central hub/bearings and in centrally supported long rotor blades; uncontrollable gusts and heavy load differences over time and cross section.

C. Power Control

¨ GT: Pitch control of slowly rotating turbine blades with low-stress doubly supported turbine blade bearings + central control of heat transfer from quick-response hot water energy stores; the extremely unlikely failure of control in one turbine or one water pond will affect less than 3% of total power delivery Þ constant availability of 97% can be guaranteed;

¨ Fossil Fuels: Complicated fuel injection at high temperatures + mass flow control through valves at high temperatures and pressures; failure of one valve stops whole power train; routine checks and/or repairs will stop the whole power train.

¨ Hydro power and wind turbines: Whole power train stops with repair/maintenance;

The GT working mechanism itself ensures the lowest possible heat/mechanical stress on all components and the absolute minimum of moving parts making it the most reliable technology.

8. Power Generation

People often feel uncomfortable with the big leap from the 50kW pilot plant to a 200/400MW power station and propose an approach in steps. Since the sucking action is directly proportional to chimney height, smaller sucking action would mean slower mass flow as also higher air temperatures in the collector and thus T^4-losses in IR radiation, a 1 000m chimney would not only be out of proportion with a 1MW or 10MW power plant but small plants would show an over-proportionally poor performance. They are too expensive for demonstration. This problem was solved by contracting the leading world expert on thermodynamics and flow dynamics of cooling towers, Prof. Kröger of Stellenbosch University, to calculate the GT power production and to guarantee his calculation, whereupon an insurance policy for a guaranteed power delivery will be issued at the end of the feasibility study.

The insurance policy will cover the cost of the collector’s enlargement to compensate the shortfall of power generation. Assuming an unlikely shortfall of 10% the collector area will be augmented by 11% at the periphery with an increase of 16% of the greenhouse area. This will restore the 100% design profit from power sales, but at the same time create additional greenhouse profits of 330% of the first 10% financial shortfall (profits from greenhouse more than twice those from power). Hence the insurance company will only supply the building loan with a low short-term guarantee-interest replacing the premium.

Prof. Kröger will by agreement publish the worst case power figures. He will close the gap between best and worst case to 10% or less. This will not be easy, since the driving force, i.e. the buoyancy difference between the air column inside and outside the chimney is very small compared to the buoyancy of the two columns themselves, augmenting every error in measurement 10 to 20-fold. For this reason Prof. Kröger has already developed a refined model of the ambient atmosphere, which will become exact with real time measured parameters of the microclimate on site. Incidentally, his first calculations on the Solar Chimney confirmed Prof. Schlaich’s figure of 200MW for the Solar Chimney as average between best and worst case. The 400MW-GT improvements were not contained in Prof. Kröger’s first calculations. They will be part of the present pre-feasibility and feasibility study.

Measurements at the low lying Sishen mine in the eastern Kalahari in South Africa showed an inversion layer of 300m thickness and 17°C temperature difference at ground level during winter nights, reducing power generation during winter by 9%. To avoid these “cold air lakes”, which are part of Prof. Kröger´s calculations above, the GTs, envisaged to be built in India, Namibia, UAE etc. will be erected on escarpments standing out of these lakes. Cold air flowing down mountain slopes will be barred from entering the collector and led to pass by. Much power can be gained by an exact determination of the microclimate based on past GT research.

Past research showed that the IR-radiation losses to the sky caused high energy losses. With the world’s leading research unit on solar glass, the Fraunhofer Institute in Freiburg, it was established that the IR-reflecting-sunlight-translucent layer of the company Interpane in combination with double-layer insulating glass will raise collector efficiency from 45% to 90% plus at modest cost and will double power output. Iron-free glass and the SA Atomic Energy Corporation’s anti-reflection layer will additionally increase power output by 12%.

Re-condensation of greenhouse-evaporated water will cut evaporation losses by ± 95%. The gains, shown above, will finally be proved during the feasibility study in two 500m glass tunnels with wind fans mounted at the small ends, resembling part of the collector. This will also prove Prof. Kröger’s flow dynamic calculations experimentally and thus remove even the slightest uncertainty from his power production forecast.

9. The Thermal Energy/Water Store

Since solar/wind power generation does normally not coincide with demand, low-cost energy stores are imperative for these technologies to be competitive. Only the Solar Chimney/GT low temperature plant has such very cheap energy stores in the form of closed water ponds at the collector’s floor in the central non-greenhouse part. When Prof. Schlaich’s 1996 energy store was not performing well, it was re-designed in South Africa in 1999 and successfully tested.

Prof. Kröger´s experimental research at Stellenbosch University proved that the new heat transfer control is of special importance. It performs extremely well and allows extension of the central quick-control energy store to six days full production and a reaction time of only four minutes from 10% to 100% power production. Though only being tested on a small scale, exact forecasts on the full energy store’s performance are conclusive and without any risk, since the heat transfer coefficients are well known, whilst the single pond contributions just add up.

The cheap seasonal store (six months) was tested in Germany and is state of the art there. Hence the proven GT energy stores do not present any financial or functional risk.

10. Conclusion

The GT technology does not pose any threat or risk to the environment or any significant structural or financial risk, as it uses only state of the art technology, though in new combination. It is dearly needed to replace the dwindling fossil energy reserves, to reverse global warming and to improve the climate through cultivation of deserts. Only a fraction of the high quality research done could be shown here. The GT is hitherto the most thoroughly researched emerging power technology, and where components were tested, the function of the whole system was also taken into account. The leading world experts working on this exciting project achieved a state of maturity which is unprecedented for an evolving technology. Without being sure of success they would not have thrown in finance and their professional weight.

In a similar unprecedented manner all problems and risks were addressed so successfully that today about 34 patents are in preparation. The diminution of financial risks by insurance policies also gives a good indication that the actual risk of structural failure or shortfall of power is negligible. Hence the risk of investment as also functional and financial failure of the GT is virtually zero.

Der GreenTower

SOLARKRAFTWERK MIT INTEGRIERTEM TREIBHAUS

Kurzübersicht

Für ein bis acht 400MW GreenTower Solarkraftwerke in Namibia,

auch in Vorbereitung für GT-Kraftwerke

in den UAE, Irak, Australien, Indien, China etc.

Stand Mai 2009

Ausgegeben durch GreenTower Limited

GREENTOWER-TECHNOLOGIE UND -KOSTEN

1. WIRKUNGSWEISE

Sichtbare Strahlung von Sonne und (bedecktem) Himmel erhitzt die Luft im glasgedeckten Kollektor, die, nun leichter, im zentralen, hohen Schlot einen Aufwind erzeugt, der Turbinen mit integrierten Generatoren am Schlotfuss antreibt. Der heutige, solar-elektrische Wirkungsgrad beträgt 4%, der theoretische (Carnot) 28%, der praktische (= Entwicklungspotential) 14%.

Pflanzenwuchs im Kollektor erhöht nach den Forschungsergebnissen (seit 1998) der Universiät Stellenbosch die Stromproduktion. Der äussere 2/3-Kollektoranteil wird gleichzeitig als Treibhaus und zur Lufterhitzung genutzt. Pflanzenverdunstetes Wasser wird rekondensiert.

2. SPEZIFIKATIONEN

Das GreenTower® (GT)-Konzept folgt Prof. Schlaich’s Aufwindkraftwerk, verbessert dieses aber mit einem Treibhaus (hohe Einkünfte), neuen internationalen Forschungsergebnissen + der einzigartigen Erfahrung im Kühlturm-Entwurf/Bau von Krätzig & Partner + dt. Experten.

Schlothöhe: 1 500m; Schlot-Æ:180 - 280m; Kollektor-Æ: 6,9km; Glasdachhöhe: 10 – 30m

Nennleistung: 400MWel (rein solar, emissionsfrei); 32 Turbinen am Schlotumfang mit integrierten Lineargeneratoren; Kapazitätsfaktor ³ 89%; Verfügbarkeit = 97%

6-Tage-Schnellreaktions + Saison-Energiespeicher Þ jederzeit volle Leistung

Kollektorfläche = 37,5km², trockener Anteil = 12,5km²; äusserer Ring = Treibhaus = 25km²

Treibhaus: Tropfenbewässerung + Humusboden (12% bis 25%); höchste Erträge, niedrigste Kosten, rein organisch (bakterielle Stickstoffdüngung); Restbiomasse → Humus im Boden

CO2-Sequestrierung/ GT + Freilandpflanzungen » 2 000MWel an Kohle-KW-Emissionen

Nur GT-Humus kann z.Zt. CO2-Sequestrierung garantieren/zertifizieren, holt CO2 aus der Luft

Entwurflebensdauer: 160 Jahre, Abschreibung ³ 80 Jahre; Bauzeit: 3 Jahre

Kosten geschätzt: nur GT-KW ± € 510 Mio; Treibhausimplemente ± € 100 Mio; Glasfabrik ± € 70 Mio; Gesamt ± € 680 Mio; Kosten stammen aus früheren Angeboten; 2,5% Inflation

3. UMWELT UND SICHERHEIT

-Emissionsfreie + umweltfreundlichste Stromproduktion durch höchste CO2-Sequestrierung

-hohe CO2-Kredite Þ hohe Einkünfte in Entwicklungsländern; Klimawandel kehrt sich um

-GTs geben Humus an Nachbarschaft ab; Wurzelwachstum 1m/ 3 Tage, Wasserspeicherung

-Bisher wertlose Wüsten können (Wasserentsalzen + Pumpen) mit Gewinn kultiviert werden

-Landbauerträge steigen von 100% im Freiland auf ≥ 270% im GT, keine Landsterilisierung

-Baueinwirkung ist über 160 Jahre verteilt, vorige GTs liefern Energie für den Bau neuer GTs

-Treibhausarbeiter sind durch Schattennetze automatisch gegen Glasbruch geschützt.

4. GREENTOWER-VORTEILE

-Gewinn ausTreibhaus (³ 2x Strom) + Stromverkauf, sowie die lange Lebenserwartung garantieren langfristig einen Strompreis von real 1,5 €c/kWh zwischen 30° Nord/Süd und bei Gleichstromübertragung 2,0 €c/kWh bis 55° Nord, d.h.. Europa, Nordchina, USA, Japan etc.

-Hohe Gewinne trotz billigsten Stroms locken Investitionen in grossem Stil an

-Bis heute hoechste Zuverlässigkeity aller Stromtechnologien, geringste laufende Kosten

-Versicherungsschutz für Entwurf, Bauausführung und Stromleistung Þ kein Investitionsrisiko

-Eigene Entsalzungsverfahren erzeugen sehr billig Bewässerungs- und Trinkwasser

-GT-Humus + -Wasserentsalzung/-Pumpen macht Wüstenkultivierung profitabel

-GT-Treibhaus + -Bewässerungsprojekte schaffen bis zu 30 000 Arbeitsplätze pro GT

-Investitionsgewinn/Jahr ³ 50% Þ Beste Investition in Strom- und Landwirtschaft

PROJEKTSTAND

1. TECHNOLOGIE

-Der GT wurde seit 1996 unter Leitung von GT Ltd bei 10 Universitäten und 31 anderen Forschungseinrichtungen auf eigene Kosten durch weltführende Experten weiterentwickelt:

-Prof Kröger, Universität Sellenbosch, der führende Thermodynamikexperte für Kühltürme, garantiert Versicherungspolicen für die Stromlieferung durch führende Versicherer.

-Prof. von Backström, Universität Stellenbosch, weltführend in langsam laufenden Gasturbinen, verbesserte den Wirkungsgrad der GT-Turbinen von 70% auf über 90%.

-Prof. Meins, Technische Universität Braunschweig, weltführend bei turbinen-integrierten Lineargeneratoren, führt eine exzellente Expertengruppe bei der GT-Stromerzeugung.

-Prof. Krätzig, Krätzig & Partner, Bochum, und Prof Harte, Universität Wuppertal, weltführend in Kühlturm-Konstruktion/-Fehleranalyse, haben den GT optimiert und verantworten Entwurf/Bau.

-Profs Niemann und Höffer, Universität Bochum, weltführend bei (periodischen) Windkräften untersuchen deren Einfluss auf den hohen GT-Schlot im einzigartigen Windtunnel dort.

-Die einzelnen Entwicklungen werden nunmehr in eine Technologie mit 34 Patenten während der Vor- und Projek(-Planungs-)Studie in Namibia zusammengeführt.

2. ANGEBOTE UND VERTRÄGE

2004 Seitdem Südafrikas EVU Eskom die guarantierten Stromlieferung an Namibia ab 2007 wegen

Kapazitätsmangels stoppte, sucht die Staats-EVU Nampower nach neuen Stromquellen.

2006 GT nach Ausschreibung in engster Wahl für ein 400MW Kraftwerk bei Walfischbai. Der

niedrige Strompreis (1,5 €c/kWh), Wasserentsalzung und Arbeitsplätze gaben den Ausschlag

2006 Vorläufiges Angebot von Nampower für einen Stromabnahmevertrag.

2006 Mündliches Angebot des Finanzministeriums von Staatsgarantien für GT-Projektfinanzierung

2007 Nach Präsentation von GT-Experten, Nampower überzeugt, dass ”die GT-Experten den

1.500m-GT-Schlot bauen und alle auftretenden Probleme lösen können” Aufforderung, ein

Angebot für eine GT-pre-feasibility study abzugeben (NamPower zahlt Hälfte der Kosten)

2007 Unterstützender Brief durch Ministry of Mines & Energy.

2007 Vorvertrag: 1 600MW (4 GTS) + Wasser an das Trans-Kalahari-Railway-Konsortium.

2007 In Rajasthan, Indien, ist ein Stromabnahmevertrag und Freihandelsstatus vorverhandelt.

2007/8 GT-Verhandlungen mit den UAE sind inzwischen in einem fortgeschrittenen Stadium.

2008 Verhandlungen mit der Regierung in Australien (CO2-Sequestrierung) sind eingeleitet.

FINANZIERUNG UND ANTEILE

- FINANZIERUNGGSBEDARF FÜR VOR- UND PROJEKTSTUDIE

Studie/ Item | Kosten in Millionen | US$ | € | Dauer in Monaten |

Bankfähige Projektvorstudie PVS | Angebot | 0,75 | 0,5 | 6, (11 vorläufige Patente) |

Bankfähige Projektstudie (PS) | Angebot + Schätzung | 37,5 | 25,0 | 24 |

Einschl.34 int. Patente | Angebot | (4,5) | (3,0) | 30, volles Technologiepaket |

Die Projektstudie (PS) wird die GT-Technologie durch 34 internationale Patente schützen und im Wert erhöhen.

2. MITTEL FÜR GREENTOWER-KRAFTWERKE

Deutschland muss bis 2020 die heutigen CO2-Emissionen von 860 Mio ton/J um 20% = 172 Mio ton/J nach den EU Richtlinien senken. Da es diese Menge an CO2-Zertifikaten z.Zt. nicht gibt, kann nur der GT die notwendigen Zertifikate aus Sequestrierung generieren. Allein die geplanten 8 GTs in Namibia generieren 120m ton/J an CO2-Zertifikaten, ohne die mindestens 8 GTs in anderen Ländern bis 2020 einzurechnen. Mithin können deutsche/europäishe Braunkohle-Kraftwerke mit den geringsten Strompreisen aber dem höchsten CO2-Ausstoss kosten- und risikolos in die geplanten 8 projektfinanzierten GTs in Namibia investieren, kostenlose Zertifikate erhalten und an den hohen GT-Gewinnen teilnehmen. Das gilt für alle grossen CO2-Emittenten in der EU. China und arabische Ölstaaten benötigen dringend GTs und haben US$ 3 Bio Bar-Reserven.

3. EINKOMMEN/ JAHRESGEWINN AUF GT-LTD-ANTEILSKAPITAL

A. Technologiegebühr von 3% auf Investition (€ 600 Mio) bei jedem gebauten GT.

B. 50,1%-Anteil an GT-Kraftwerken erzielt nach Rückzahlung € 300 Mio plus pro GT.

C. Managementverträge erzielen bei 5% Gebühr Jahresgewinn von 1,5% von € 600 Mio/GT.

D. Projekt-/Planungsstudien: Bei 2,5% per GT (€ 600 Mio) erzielen 0,9% Jahresgewinn.

E. Reinvestierung der og Einnahmen bringt steuerfreien, exponentiellen Kapitalzuwachs.

ZUSAMMENFASSUNG

-Der GT wird nach Abschluss der Vor- und Projektstudie die am gründlichsten untersuchte/ getestete neue Stromtechnologie sein. Die Windtunneltests in der Uni Bochum beseitigen jedes Restrisiko beim 1 500m hohen Schlot Þ eine der sichersten je gebauten Strukturen.

-Die Bauzeit von 3 Jahren ist deutlich kürzer als die von Kern- oder Kohlekraftwerken.

-Die Projekt- (= Planungs-) Studie gibt den Aneilseignern Anteil an der besten und billigsten Stromtechnologie mit dem Potential, 70% des Weltstromverbrauchs zu decken.

-CO2-Sequestrierung z.Zt. nur mittels langzeit-stabilem GT-Humus zertifizierbar – direkt aus Atmophäre ohne teure Abtrennung; Chance, dass untertage verpresstes CO2 ausgast ≥ 99%.

-Der GT ist durch ein Technologiepaket mit ± 34 Patenten am Ende der PS geschützt.

-± 11 vorläufige Patente schützen kurzfristig die GT-Technologie am Ende der PVS.

-Die Wirtschaftlichkeit ist bereits nachgewiesen, die Studien beweisen nur die hohen Gewinne.

-GT Ltd/AG startet als Technologiegesellschaft, wird aber auch zur Produktionsgesellschaft für Strom, Nahrung, Wasser + Humus; GT-Kraftwerks-Beteiligungen bringen hohe Gewinne.

-Ein hochkompetentes Team treibt die GT-Technologie an. Die Mitglieder sind stolz darauf.

-Obwohl die GT-Technologie mächtige und teils skrupellose Konkurrenten hat, werden der drohende Mangel und die Preissteigerungen fossiler Energien den Durchbruch bringen, weil nur der GT die Welt vor Smog, Hunger und and Wirtschaftskrisen bewahren kann.

-Viele Arbeitspätze und Wasserentsalzung öffnen dem GT zusätzlich Türen in vielen Ländern.

-Der GreenTower ist eine lohnende Investition mit hohem Wachstumspotential. Seine Basis-produkte wie Strom, Wasser, Nahrung und Humus finden immer Absatz.